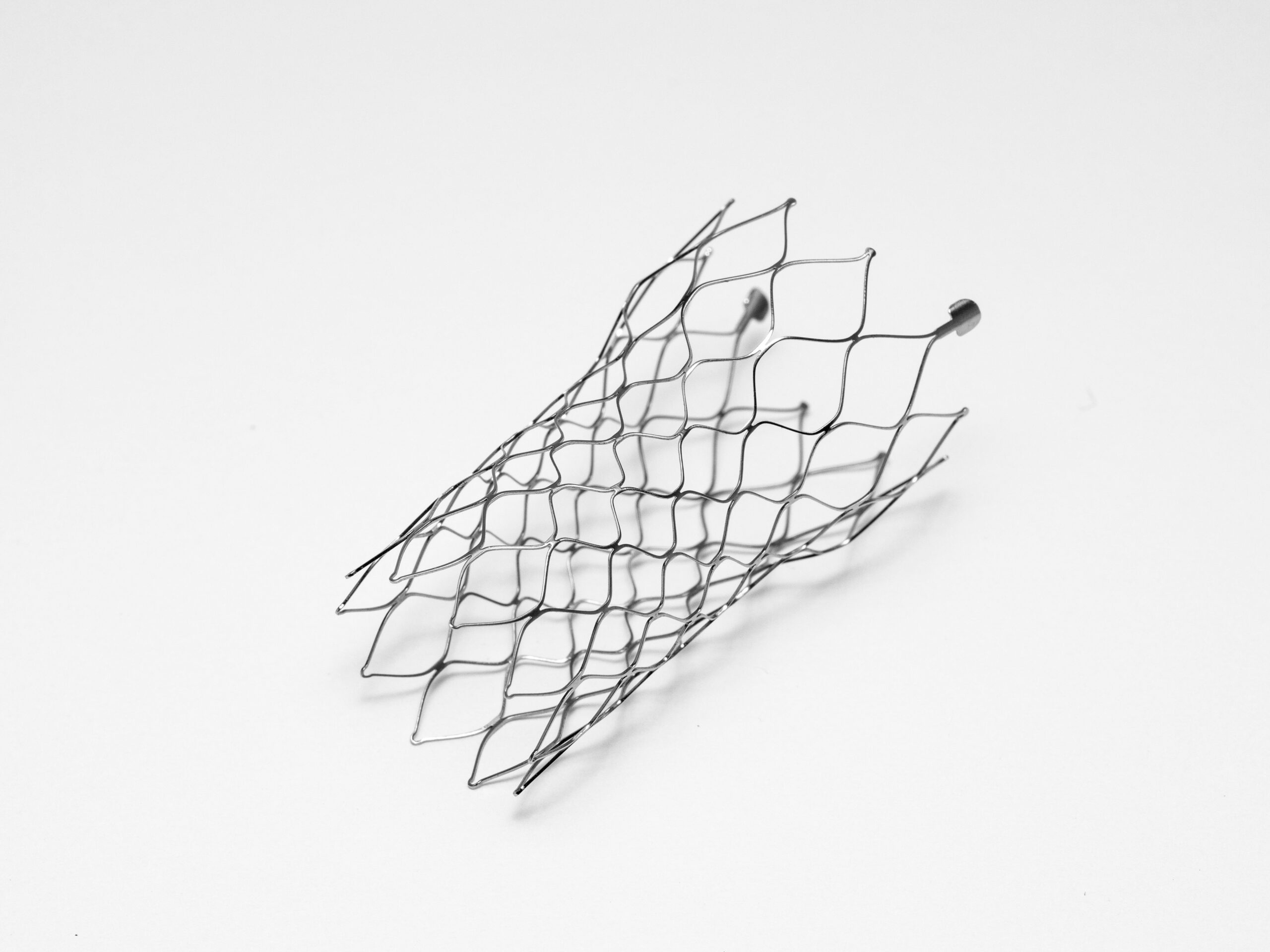

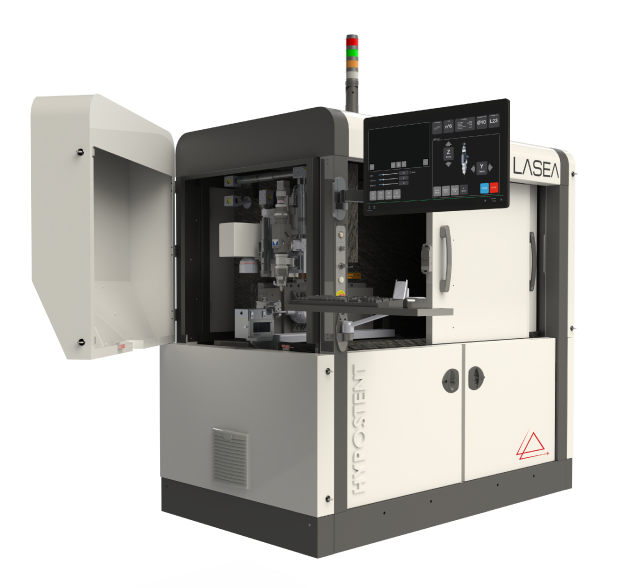

From stents and catheters to micro-needles and implants, laser micromachining enables the production of ultra-precise medical components with no physical contact or tool wear. Our laser systems are engineered to handle even the smallest tube diameters with total control and consistency.

Industries served

Luxury

Crafting perfection for the world’s most iconic brands.

MedTech

Enabling life-saving technologies through unmatched laser precision.

Electronics

Powering performance, repeatability, and miniaturization at scale.

Aerospace & Defense

Enabling lighter, stronger, and smarter components for mission-critical performance.

Research & Academics

Enabling breakthroughs in science and education.

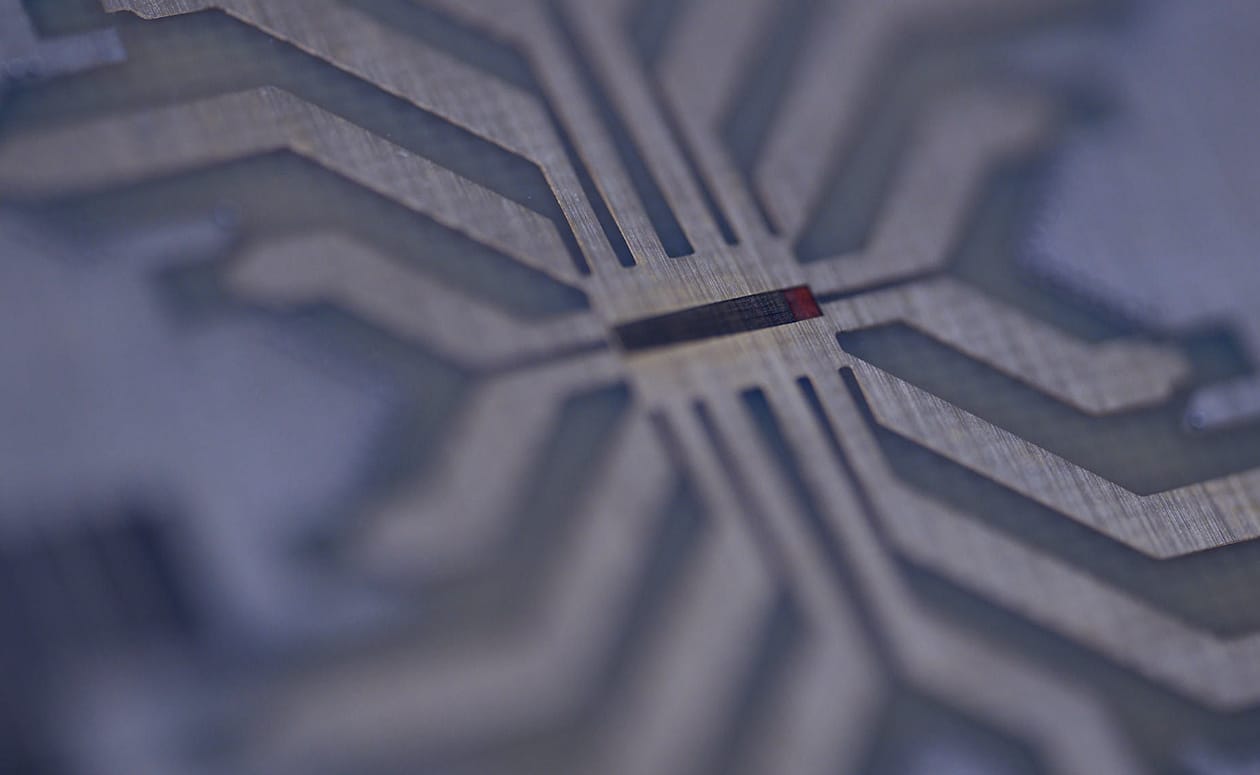

Precision where it matters most

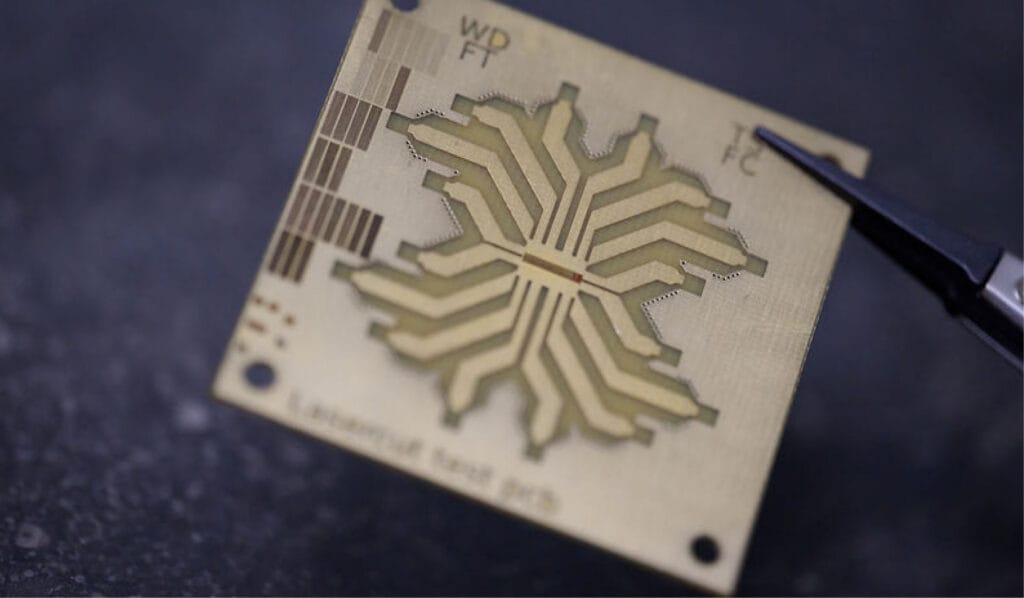

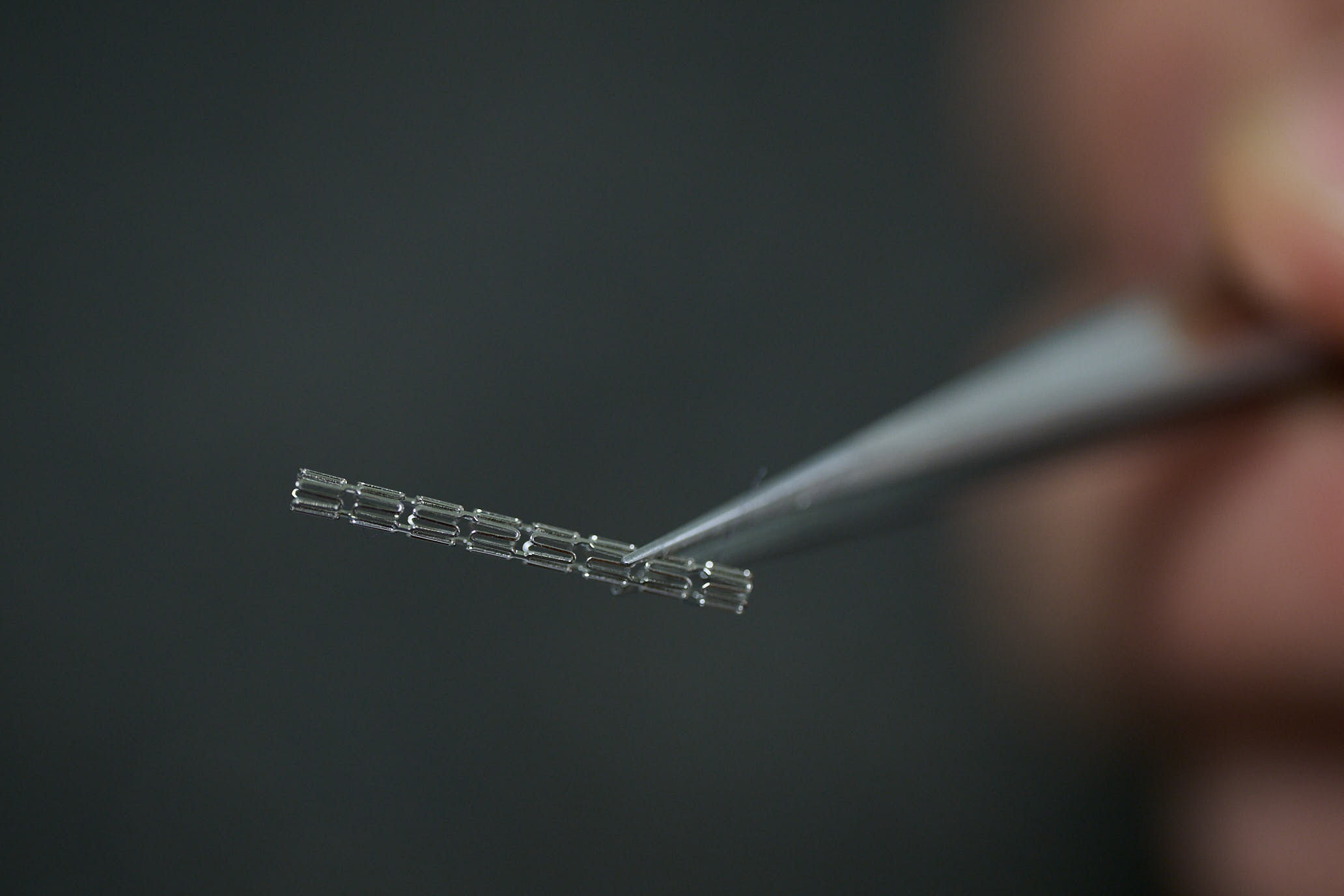

Laser micromachining of tubes and microtubes enables non-contact processing of complex geometries on materials used in high-stakes medical applications.

Clean, burr-free cutting and drilling

Accurate processing of diameters <0.5 mm

Zero thermal damage or material distortion

Works on Nitinol, stainless steel, and biopolymers

Full DXF-to-part workflow with minimal waste

From words to action

Where tubes micromachining drives results

Explore how our laser micromachining solutions enable next-gen performance in medical manufacturing.