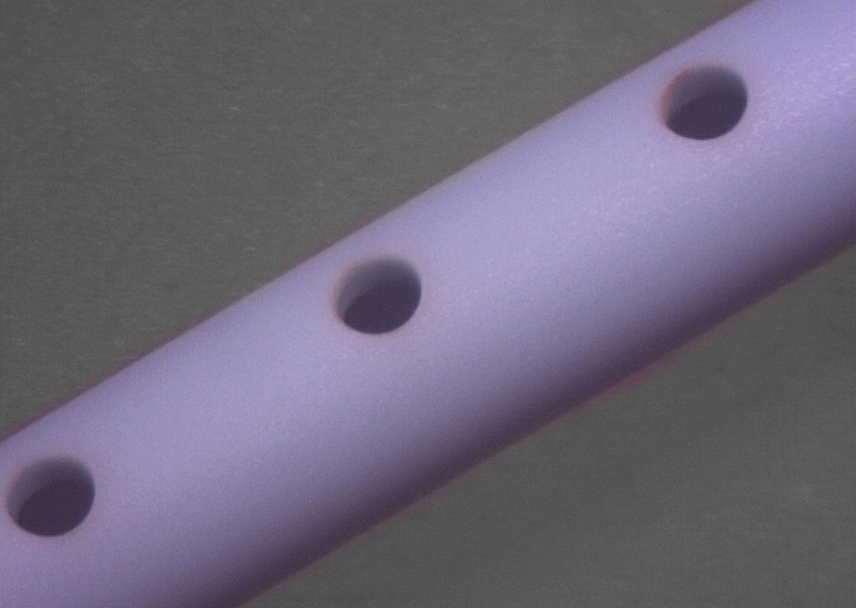

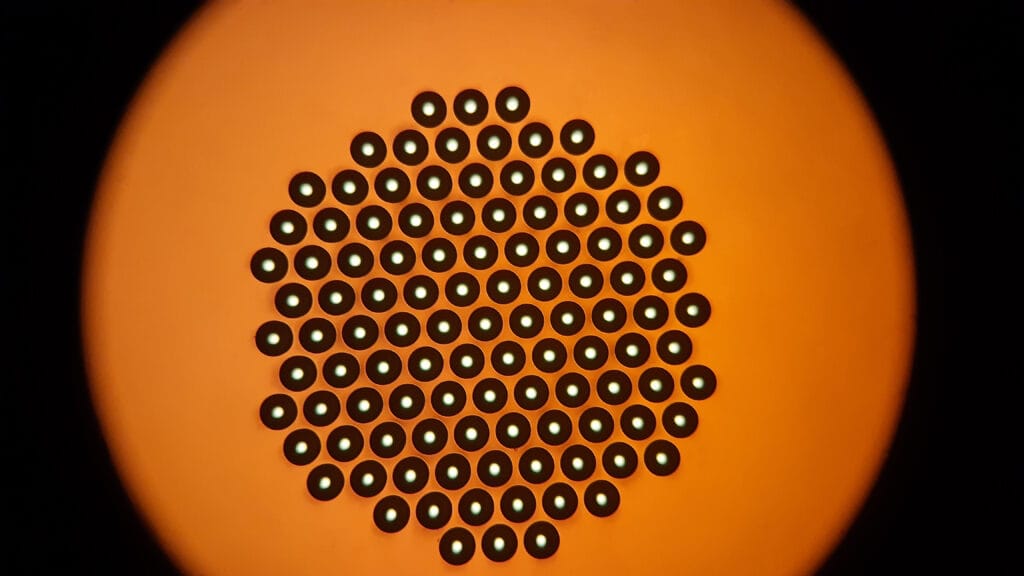

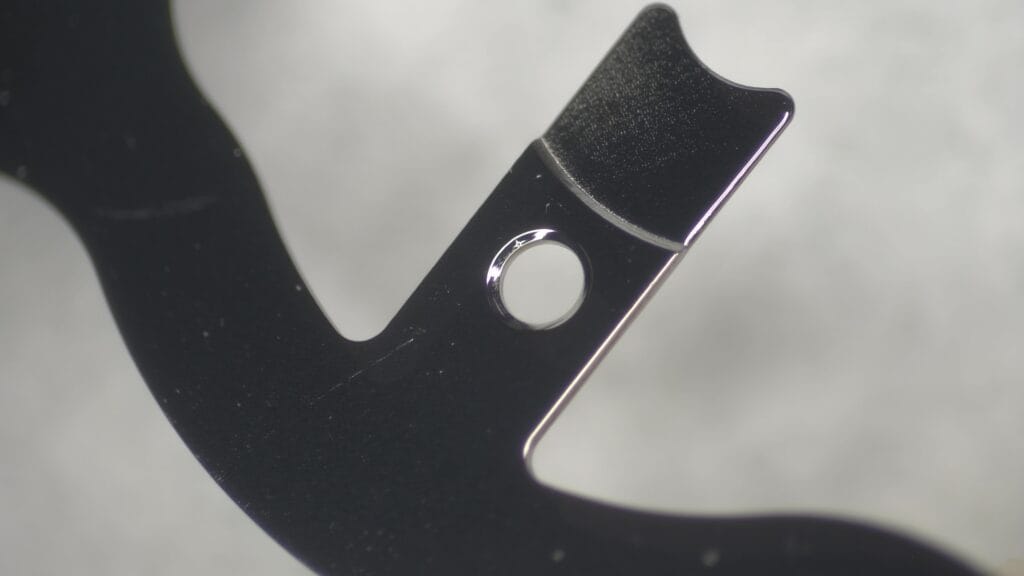

From injectors to microelectronic components, laser drilling delivers fast, accurate results across all materials. Clean holes, straight walls, zero contact. High quality on polymers, thanks to excimer technology.

Industries served

Luxury

Crafting perfection for the world’s most iconic brands.

MedTech

Enabling life-saving technologies through unmatched laser precision.

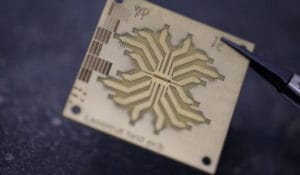

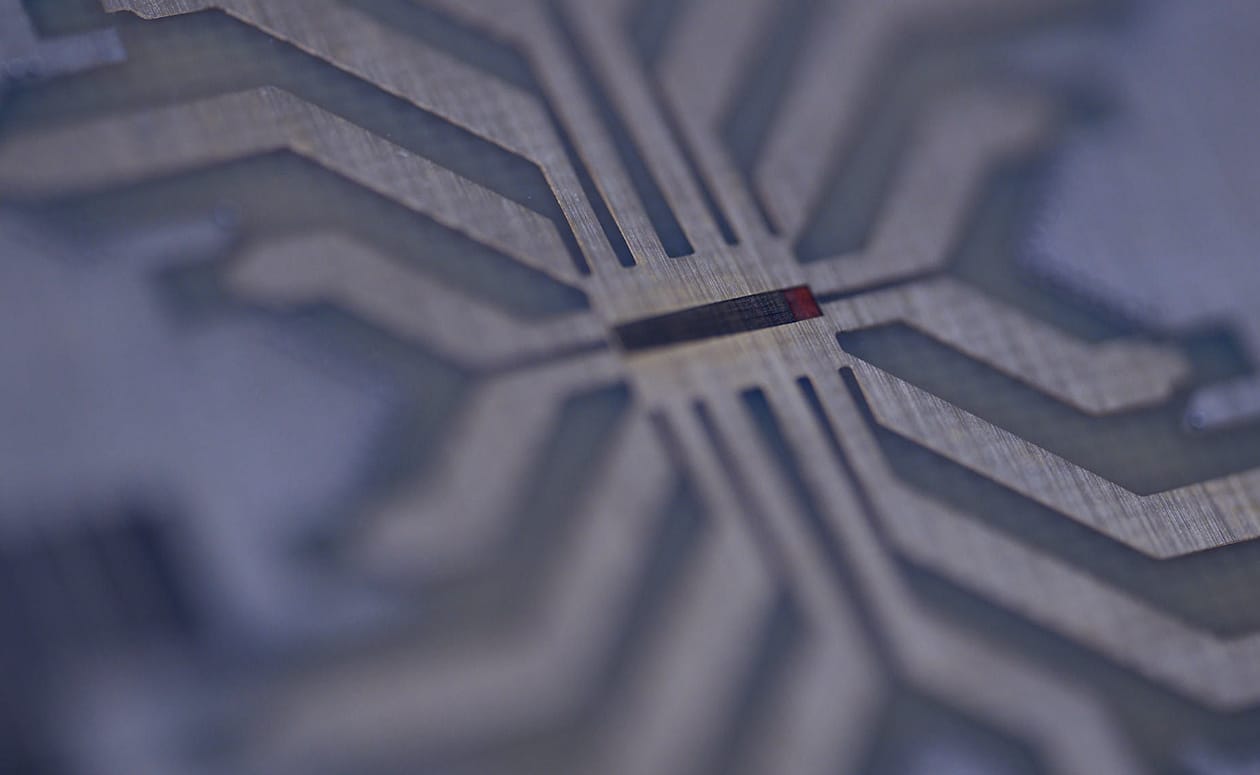

Electronics

Powering performance, repeatability, and miniaturization at scale.

Aerospace & Defense

Enabling lighter, stronger, and smarter components for mission-critical performance.

Research & Academics

Enabling breakthroughs in science and education.

Go deep, stay sharp

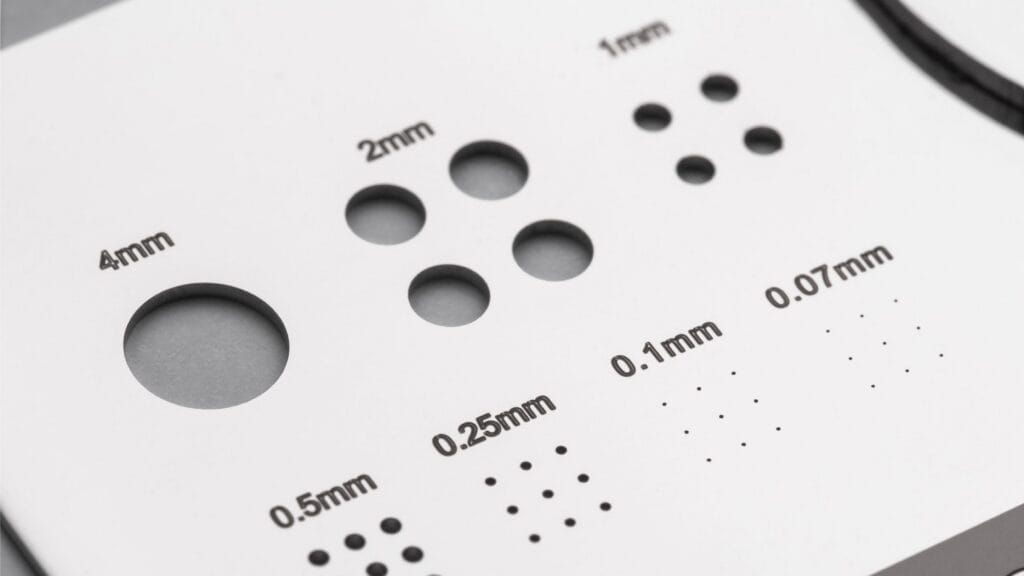

Laser drilling removes material with micron-level accuracy – minimizing damage, maximizing cleanliness, and supporting high-density designs.

Burr-free, carbon-free hole creation

Compatible with hard and fragile materials

Multiple strategies: percussion, helical, cutting, and precession

Controlled diameter and taper angle

Ideal for micro-nozzles, injectors, and fine features

From words to action

Where Laser Drilling Makes the Cut

Discover how high-precision drilling supports new performance standards in compact and complex parts.