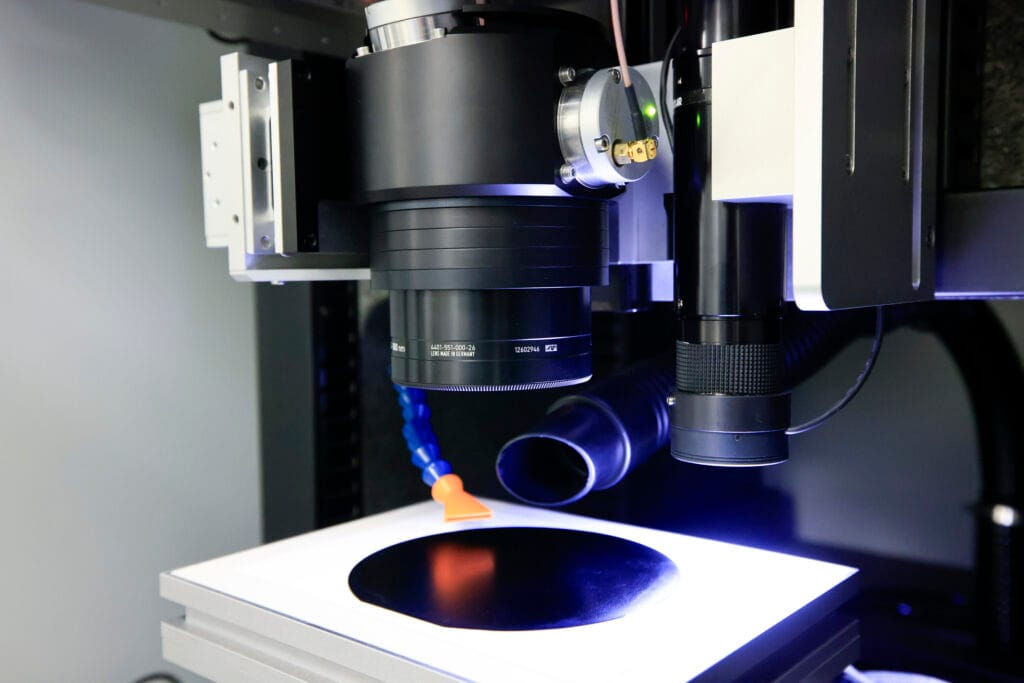

Laser Lift-Off (LLO) with Excimer technology enables the clean, precise separation of thin functional layers from transparent substrates – ideal for flexible electronics, displays, and microfabrication.

Industries served

Luxury

Crafting perfection for the world’s most iconic brands.

MedTech

Enabling life-saving technologies through unmatched laser precision.

Electronics

Powering performance, repeatability, and miniaturization at scale.

Aerospace & Defense

Enabling lighter, stronger, and smarter components for mission-critical performance.

Research & Academics

Enabling breakthroughs in science and education.

Separate cleanly, without damage

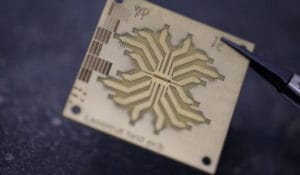

Laser debonding (LLO) uses UV lasers to lift off layers without contact, chemicals, or heat damage to the substrate.

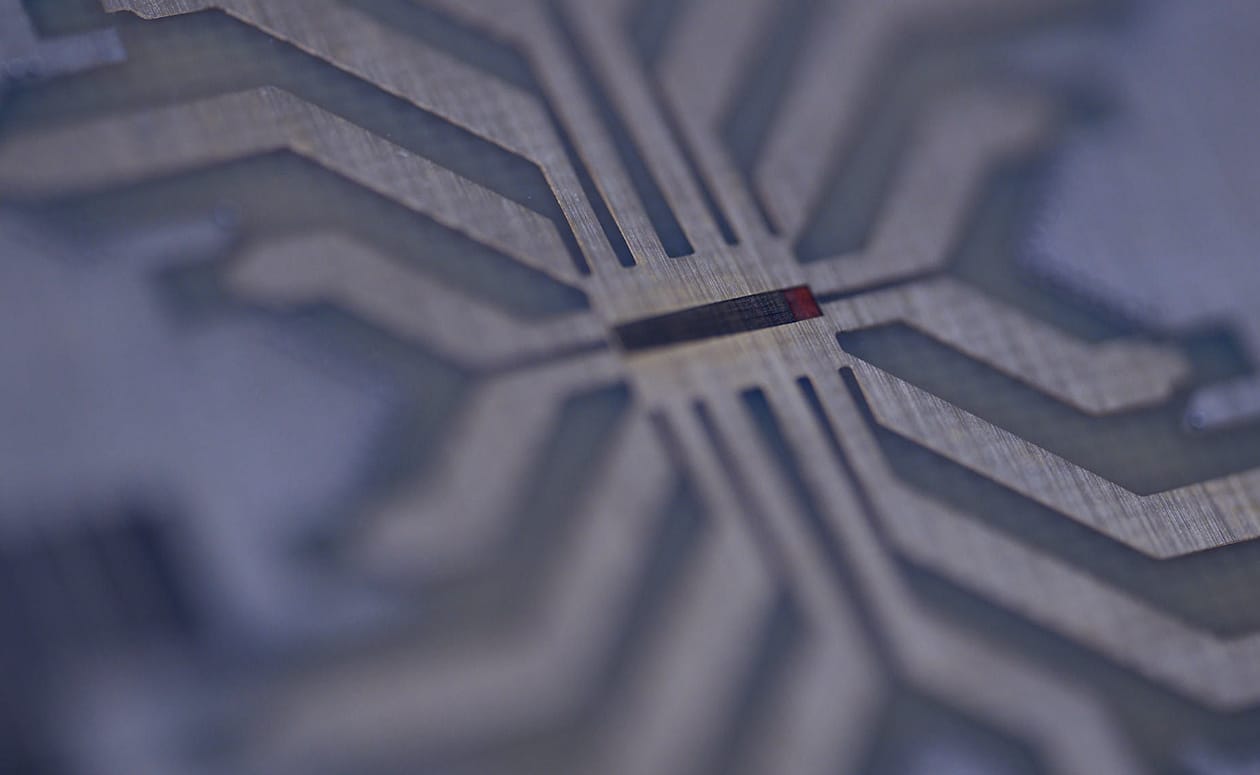

Clean separation of thin layers (e.g. polymers, films)

No mechanical stress or residue

Ideal for transparent substrates like glass

Supports flexible and hybrid component design

From words to action

Where Debonding Drives Results

Precise separation enables innovation in materials and device assembly.

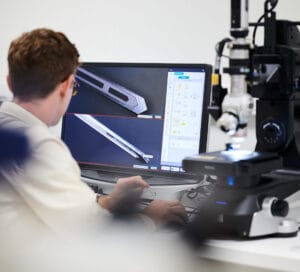

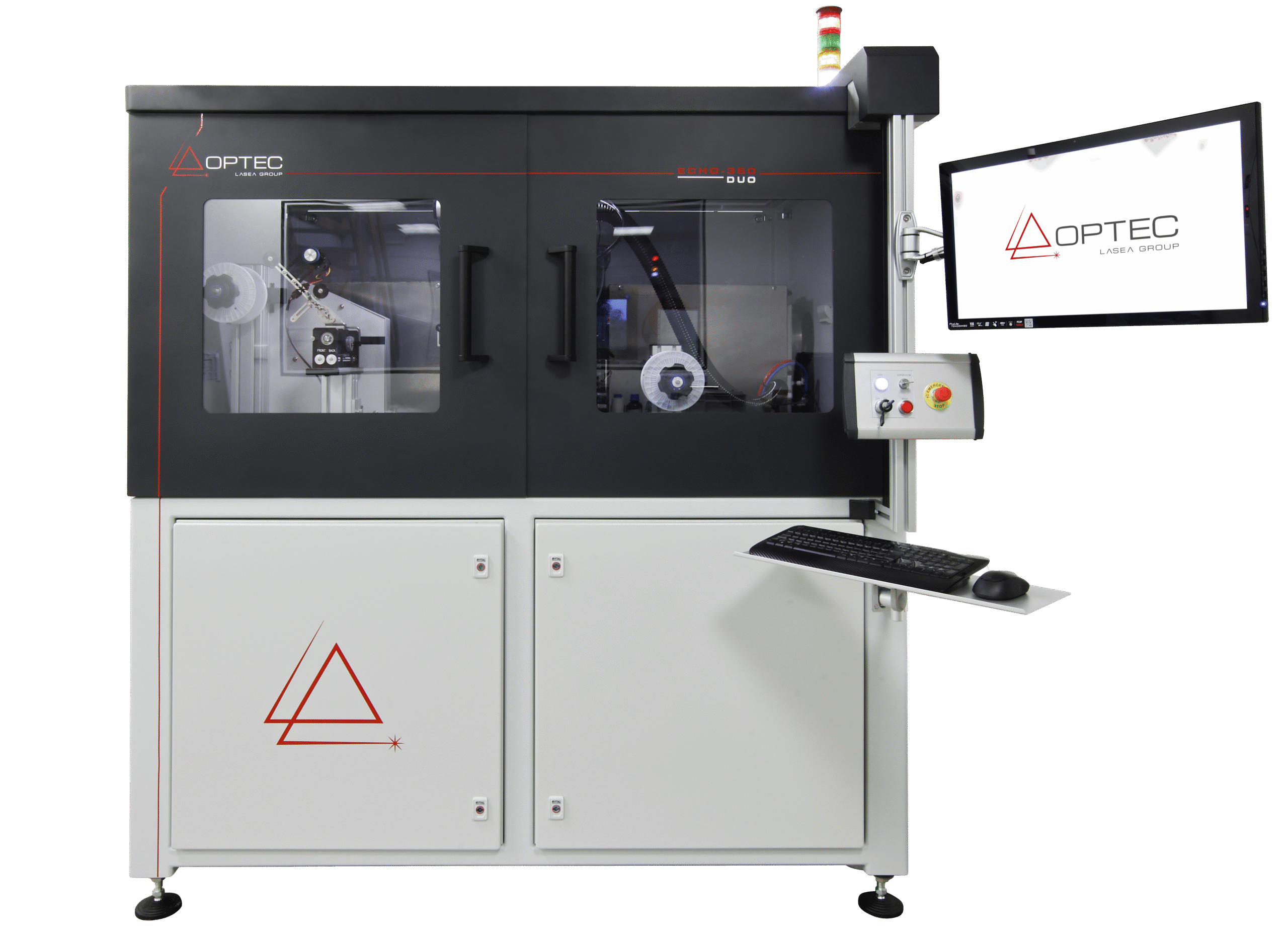

The right tools for high-impact results

Our UV laser systems and motion modules enable clean, controlled debonding with repeatable precision.

Discover our machines

Scroll